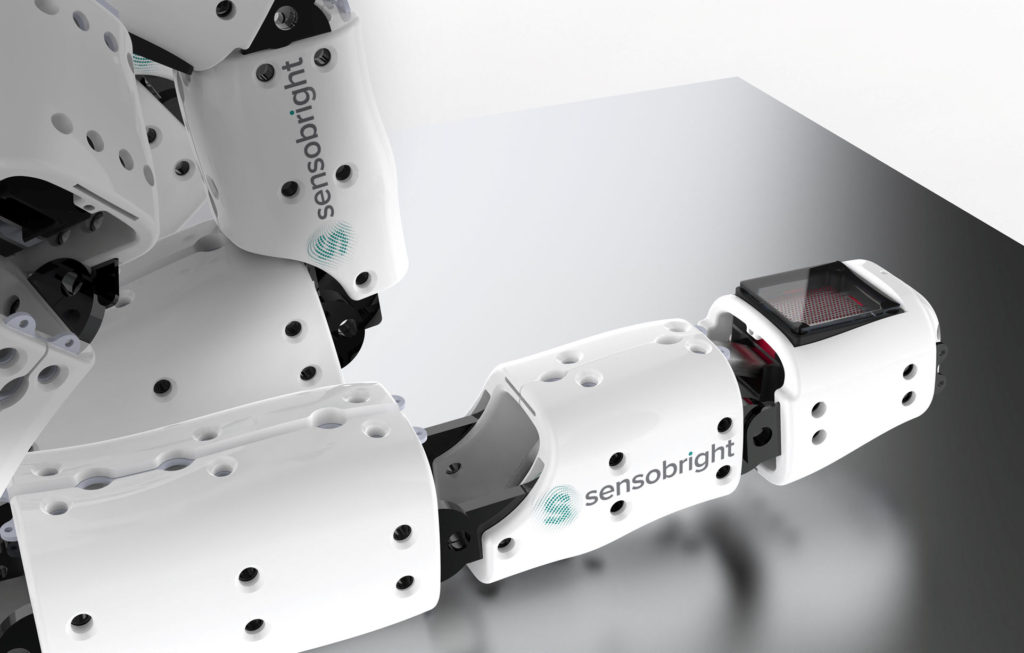

All stages of the manufacturing processes are staged in-house at our Beaverton, Oregon facility. Sensobright has invested in the latest equipment for R&D, analysis and high-precision machining. From design to production every step is initiated by Sensobright in order to accelerate partnerships and commercialization of our end products.

All stages of manufacturing processes are made in-house with company owned machineries. Sensobright Industries LLC has the most professional equipments for R&D, Analysis and the highest precision machining. From design to production every step accomplished with company assets.

* 30 tool magazine

* 64” x 32” x 30” (1626 x 813 x 762 mm) X,Y,Z absolute travels

* 10,000 rpm ct-40 spindle.

* High pressure, through spindle coolant.

* High pressure through spindle air blast (for dry machining).

* Fully integrated 5th axis controller with 32 GB internal memory(for complex geometries)

* Tilting and indexing rotary table, 24” (650mm) platter.

* Haas DS 30-Y

* Dual Spindle CNC lathe with Y axis and Sub spindle.

* Live Tooling 6000 rpm (axial and radial) Live C axis (spindle).

* 8” (250mm) main Chuck and 7” (200mm) sub spindle chuck.

* 18” x 23” (457 x584mm) working envelope.

* Thermoplastic and Silicone capable.

* 145 ton clamping force.

* 8 zone mold heating, up to 15 kw.

* Mold size capacity (between rods) ( 20” x 20” or 500mm x 500mm)

* 10 position water manifold (7 for mold)

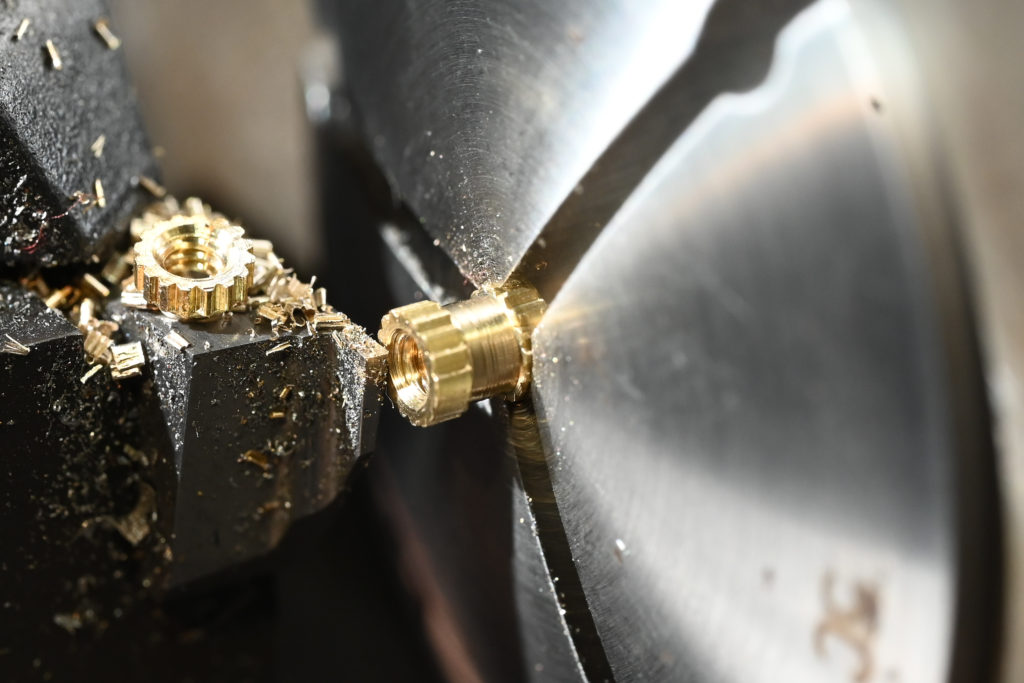

Our manual machine shop is well tooled for the prototype and light production environment.

* 13” x 40” geared head Engine lathe with DRO and collet closer

* 9 x 42 Turret Mill with DRO

* 8” x 12” horizontal & vertical Band Saw

MANNCORP MC389F3-V:

3-Head Pick and Place System w/ 3-Stage Conveyor

The MC389 SMT pick and place system has three heads and active vision allowing accurate placement of any SMD (including 01005 chips, µBGAs, and 12-mil pitch QFPs). With A placement area of 650 mm x 460 mm (25.6″ x 18.1″) and a capacity for up to 160 Smart Tape and Stick Feeders.

MANNCORP CR4000C:

5-Zone Convection Reflow System

CR4000C 4-Zone SMT Reflow Oven

A 4-zone medium-volume model with a compact footprint providing, lead-free capability.

Fully integrated and automated

MANNCORP AP430:

Fully Automatic Inline Stencil Printer

The AP430 is a high-precision, fully automatic SMT stencil printer with a print area up to 400 x 340 mm. It accommodates stencils from 470 x 370 mm to 736 x 736 mm. Vision alignment allows for quick PCB positioning. High-quality prints are guaranteed with the printer’s 4-point ball screw for both the blades and stencil-PCB separation.

MANNCORP BC100X-W1:

Pass-Through Conveyor

2 x, BC100X Pass through conveyors for system component linking, visual inspection, PCB buffering, and assembly functions within the production line.

* FDM Printers (Build volumes of 330 x 240 x 300 mm and 200 x 148 x 150 mm) Ultimaker S5 , Markeforged Carbon Fiber Printer,

50 W Fiber Laser

* SLA Printers (Build volumes of 335 × 200 × 300 mm and 145 × 145 × 185 mm) Formlab Form3L , Formlab Form3

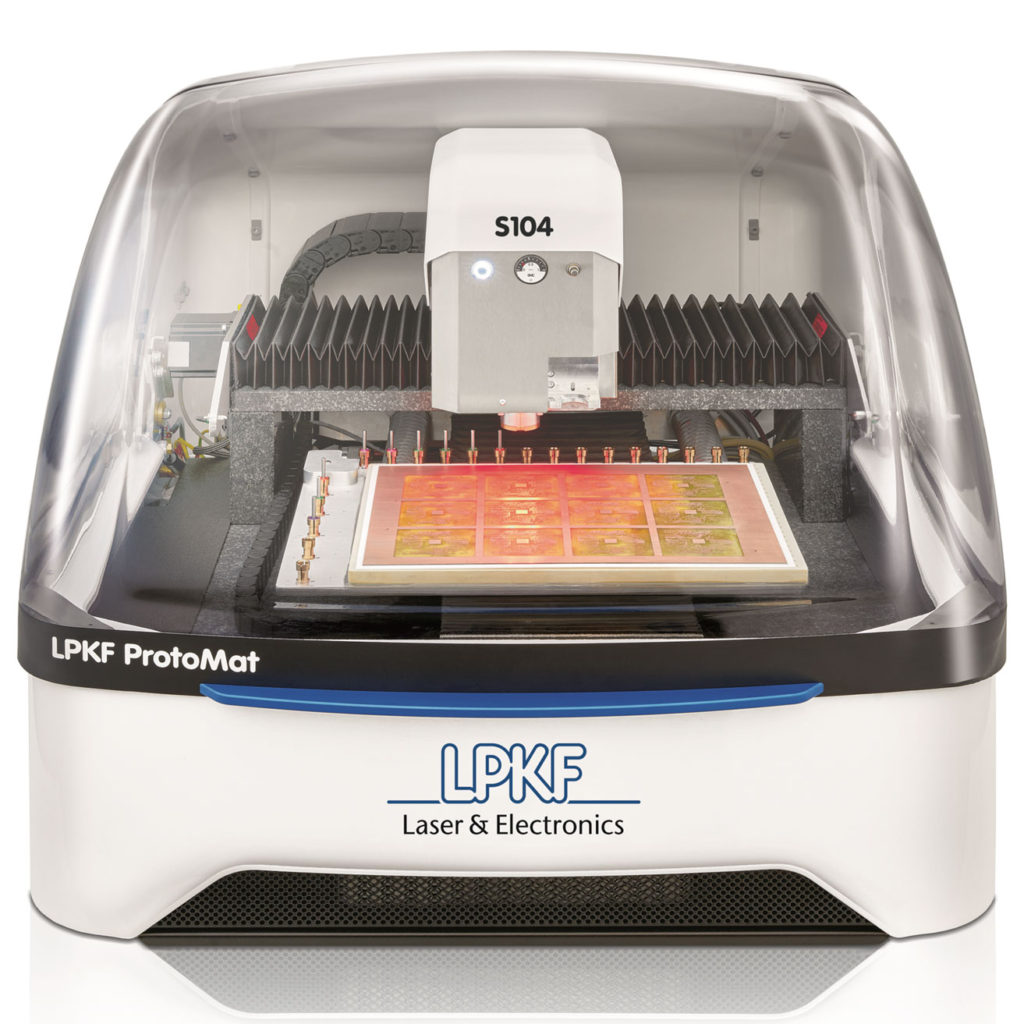

* The LPKFProtoMat S104 is a user friendly Sensor-controlled, milling machine.

* The material and copper thickness are measured automatically and enable the exact calculation of the required milling depth.

* The S104 is equipped with 20 tool positions, automatically changes the corresponding tools during the production process. Depending on the intrusion depth, the conical milling cutters generate different insulation channels. The automatic milling width adjustment also ensures that the milling contour has a constant and correct width. If required, the integrated dispenser can then apply solder paste to solder pads fully automatically.

* Material capacity, 250 mm x 330 mm x 26 mm ( 9.8” x 13” x 1”)

* Hardness tester

* Stereo microscope with camera

* F.T.I.R Spectroscope

* Durometer

* Tensile strength tester (custom built)

* Machine in process Part probing Haas VF-6