Magic Silicone is a thin and dark colored silicone pad designed to measure/quantify touch and convert it to digital data. We use this technology in our Smart Surface, and it can be manufactured in any uniform or non-uniform shape. It is essentially a touch surface that provides data when pressure is applied to it. When a stimulus is applied to the Smart Surface pad, it changes color proportionally to the magnitude of the force applied, which is captured and analyzed with our software enabling it to control peripheral functions.

Sensobright Smart Surface technology contains our unique silicone (Magic Silicone) that changes color proportionally in response to any force or pressure applied to it. it is one of our 140 internationally patented technologies. Magic Silicone creates a force map on the surface based on color intensity, allowing for the analysis of force distribution. Smart Surface technology is compatible with any pliable surface, including textiles, plastics, and metals, and is resistant to fluids and magnetic interference, allowing for versatile use under harsh conditions.

Sensobright Smart Surface can even function as a touchpad itself, providing touch data from any flexible layer which is added on top. This layer can be made of any flexible material, such as artificial leather, fabric, or even paper, and can be in any uniform or non-uniform shape, presenting endless possibilities for customization and use. Surgeons and dentists can use a Smart Surface powered touchpad while wearing gloves. Your everyday couch, embedded with Sensobright Smart Surface, can control your TV like a remote or operate your computer like a mouse. imagine opening your car windows or controlling its multimedia system just by touching or sliding your fingers on the armrest’s leather.

Smart Surface’s force measurement resolution and sensitivity are flexible and can be adjusted to sense forces as low as 10 grams or as high as 10 Kilograms.

Smart Surface can measure, track, and convert 10+ stimuli into digital data simultaneously. Users can control peripherals by sliding fingers on any pliable surface, which is converted to touch data. Examples include controlling multimedia systems, automotive functions, and medical/dental equipment

In addition to the increased resolution in the X/Y axes, the Smart Surface sensor can feel the depth of the object in the Z axis.

Stimulus to the Smart Surface creates a force map proportional to the applied force, Enabling the depth of the input to recreate the shape of the object through image processing techniques.

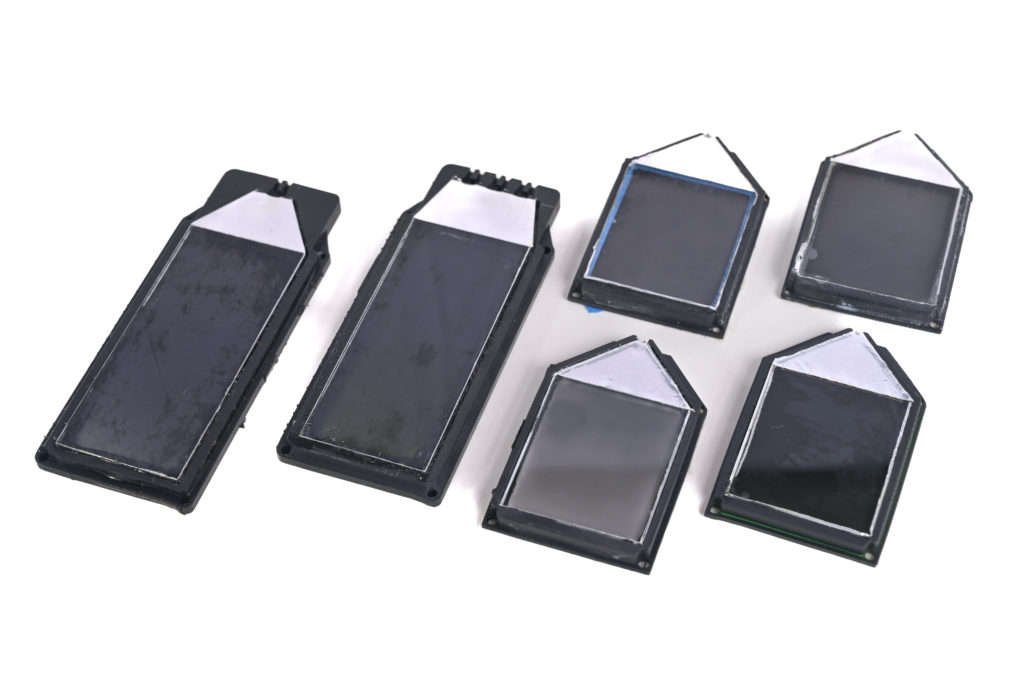

Sensobright’s Smart Surface can be used to conform to any given shape. Regardless of shape, any surface can be easily enabled with layered Magic Silicone.

Sensobright’s Smart Surface cartridge is modular and can be customized for various sensitivity ranges and size constraints.

Smart Surface is a Plug & Play solution requiring only a single USB connection to collect and translate data, regardless of the measurement surface size, force measurement resolution or simultaneous inputs.

Smart Surface is immune to fluids and magnetic interferences. Doctors can use Smart Surface while wearing bulky surgical gloves covered in fluids, an excavator operator can use Smart Surface with grease covered fingers, and soldiers can use Smart Surface next to radar towers with high-levels of electromagnetic interference.

The surface can be easily maintained and cleaned, unlike other touch surfaces and mechanical controls.